Choose your journey

Automation for every need

Flexible logistics with automated solutions

Step-by-step automation

Modular thinking

Automating your material handling processes can seem complex, but often the material flow throughout your site is quite logic, regardless if it's a warehouse or a production site. With our systematic approach we can easily find common functions that can be identified as configurable modules for repetitive use. This is the Toyota way of working: separating repetitive flows from unique ones within the process.

Lean thinking

Automated guided vehicles (AGVs) are ideal to use for your repetitive flows. Together we will identify the flows where automation will add the most value and take on your automation journey step by step. When we have identified which flows to automate, lean thinking will help us eliminate waste, and standardise processes to make automation smoother.

Let’s take a look at this manufacturing site to see which processes can easily be carried out by AGVs and take the first step...

Where would you like to start your journey?

In the put-away area pallets are transported from the inbound area, typically floor buffers, to a storage area, which is often a floor buffer or racking.

In production sites or warehouses there is always a need for replenishment of material such as pallets with parts that are taken to the production lines or picking areas that are restocked.

Where pallets are moved, there are often simple transportations from one specific station to another specific station. In distribution centres where pallets are directly transported from inbound to outbound this is called cross-docking.

In a warehouse or manufacturing site, there are always a lot of empty pallets as goods have been used or picked. Empty pallets are also needed to place picked items or finished goods from the production on.

Pallets with finished goods are picked up at a temporary storage or the wrappers close to production or picking areas, and dropped off at the outbound area, typically floor buffers or deep stacks, waiting to be loaded into lorries.

Our automated vehicles

Automated warehouse trucks

- Designed to automate repetitive pallet handling

- Allows for pallet transport, block stacking, mixed pallet handling and high-level storage

- Manual operation possible

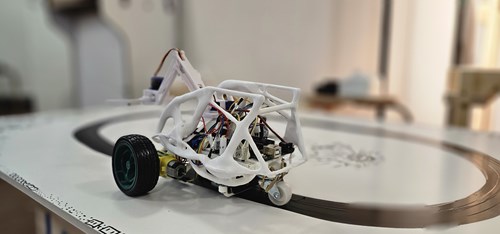

Automated carts

- Ideal for light goods handling

- Simple installation and programming

- Variety of load carriers

Semi-automated shuttles

- High-density, deep storage solution with 80% space utilisation

- Increased throughput

- Ideal for coldstore operations

- Also fully automated solution available with Swarm automation storage

Integrated solutions

Full turn-key projects

We deliver complete integrated logistics solutions from concept to implementation. Whether you’re looking into increasing your output, flexibility or resilience; our Systems Integration division will work with you in designing systems based on your data and needs. We will execute and commission full turn-key projects and support your operation through our service network.

Wide expertise

Our systems integration group specialises in state-of-the-art automation applications for order preparation, product sortation and high-density storage technologies. Controlled with modular Warehouse Execution Systems (WES), these are designed to optimise our customers’ material handling operations.

Close co-operation with Vanderlande

We also work together with our sister company Vanderlande, global market leader for value-added logistic process automation, along which we offer a wide range of fully automated solutions for airports, warehouses and the parcel industry.

Our automated offer

In order to optimise efficiency and flexibility in your warehouse, Toyota offers different types of automation products and components. These will support you in your journey to automate material handling processes.

Contact us

Contact us

First name Last Name

Logistics Solutions Manager

+12 345 6789

firstnamelastname@toyota-industries.eu

Simil Bertilsson

Simil Bertilsson

Alexander Thiel

Alexander Thiel

Stefan Carlsson

Stefan Carlsson

Magnus Oliveira Andersson

Magnus Oliveira Andersson