What type of wheels do you need for your truck?

Wheels for Hand Trucks

Your truck needs the right type of wheels in order to perform optimally. The selection of the wheels depends on the application and environment in which the truck will be used. We offer different materials for the wheels to suit your needs. You can choose between single or bogie wheels depending on the usage of the truck

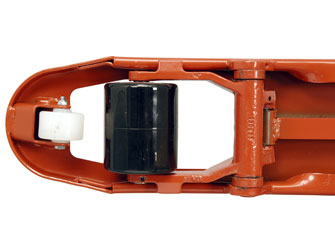

Bogie wheels are better suited for uneven floors. The load is distributed between several wheels, decreasing the point load and point friction and causing less individual wheel wear.

Single wheels are preferred on even floors and enables easy turning. The wear on a single wheel, however, is higher. A single wheel is always combined with a climbing wheel at the fork tip for easy handling of pallets on the long side.

Different wheel materials for Hand Pallet Trucks

The choice of the steer and fork wheels depends on the price, the type of application, usage intensity and the type of surface the truck will be used on.

Nylon:

- Easy rolling wheel on hard, even floors

- Hard and durable

- Best choice when the load is heavy

Polyuretan:

- Preferred when a low noise level is required

- Makes heavy loads slightly harder to pull

- Suits all kinds of application

Powerthane:

- Noiseless travel

- Better durability than a rubber wheel

- High wear resistance

Rubber:

- Very quiet

- Provides good grip on wet/slippery floor

- Antistatic version to minimizes electrostatic disharge

Iron:

- Suitable for heavy industry

- Easy rolling wheel that prevents chips or small items from sticking to the wheel

- Very long life time

Wheels for Powered Pallet Trucks

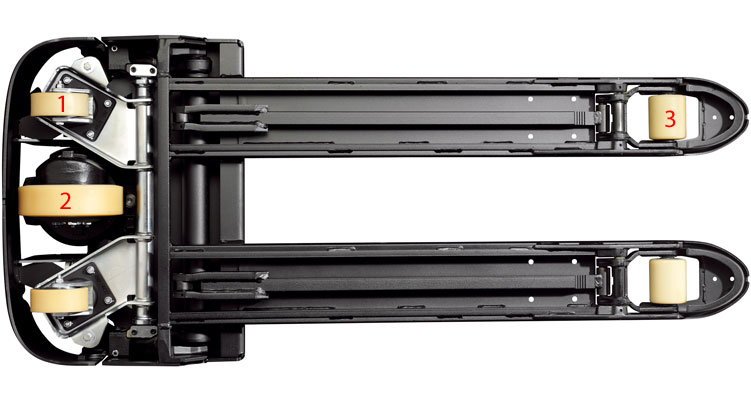

1)Castor wheel: When the truck turns or passes a bump, pressure increases on one castor wheel as a result of compression of the spring. Thanks to the torsion tube, the other spring will compress by an identical amount. The truck remains stable and will never start to rock and travel like a 'walking duck', a classic phenomenon when spring forces do not interact.

2)Drive wheel: Because of the central placement of the drive wheel, the machine does not pitch when the wheel regains its grip after spinning, e.g. on wet floors and ramps. With a drive wheel placed off-centre, considerable lateral movement can occur in these situations.

3)Fork wheel: Possible to choose between single or bogie fork wheel. Single for easy manoeuvring and positioning for long side handling and Bogie for easy climbing on uneven surfaces and heavy loads.

Different wheel materials for Powered Pallet Trucks

The choice of the drive and fork wheels depends on the price, the type of application, usage intensity and the type of surface the truck will be used on.

Friction

- Provides excellent grip, even on

moist surfaces - Does not leave marks on floors

Vulkollan Quartz

- Causes a sand paper effect that

results in slight wear on the

surfaces - Excellent grip

Vulkollan

- Hard-wearing wheel that can handle very high loads

- Ideal choice in heavy-duty applications

Topthane

- Intended for normal load handling

- Provides good grip

Polyuretan

- Cheaper alternative designed for less intensive applications

- Suits all types of applications